The wirewound resistors are an electrical passive component that has been limiting current. It is done through the wire material featuring high resistivity. Their resistive elements exist out of the metallic wire insulated that has been winded around the non-conductive material core.The resistive elements are existing out of metal wire that is insulated and winded around a non-conductive core material. Such resistors have been typically composed of copper-nickel-managese called as the “Manganin” or Nichrome materials (nickel-chromium). These kinds of resistors have been composed of manganese, nickel and copper. It also includes nickel-chromium or Nichrome materials. The wire wound resistors have been the oldest resistors kinds that have been manufactured in the present. These may be produced very accurate and has excellent properties of low resistance values and high power rating.

The construction of a wire wound resistor varies to certain factors which involve the choice and manufacturing of material used depends on how the resistor is used in the circuit. The resistance value varies on the resistivity of the wire including its length and even the cross section. For higher tolerance measurement, resistance value must be measured. This is to identify the accurate cut for the wire length. In order to obtain a higher resistance, the wire diameter must become small enough and the length should be quite long.

The wirewound resistors are naturally providing inductance and capacitance which affect the flow of current in the alternative current circuits. Because of the design principles of a wire wound resistor, this obtain poor frequency properties in all resistor types. There have been various ways of applying the winding and they depend on the resistor application. Through the DC current, there will only be a few problems in terms of winding compared to the AC current due to the self induction and parasitic capacity. To get rid of effects, there were several types of winding that are existing which include flat former winding, bifilar winding, and Ayrton-Pertty winding.

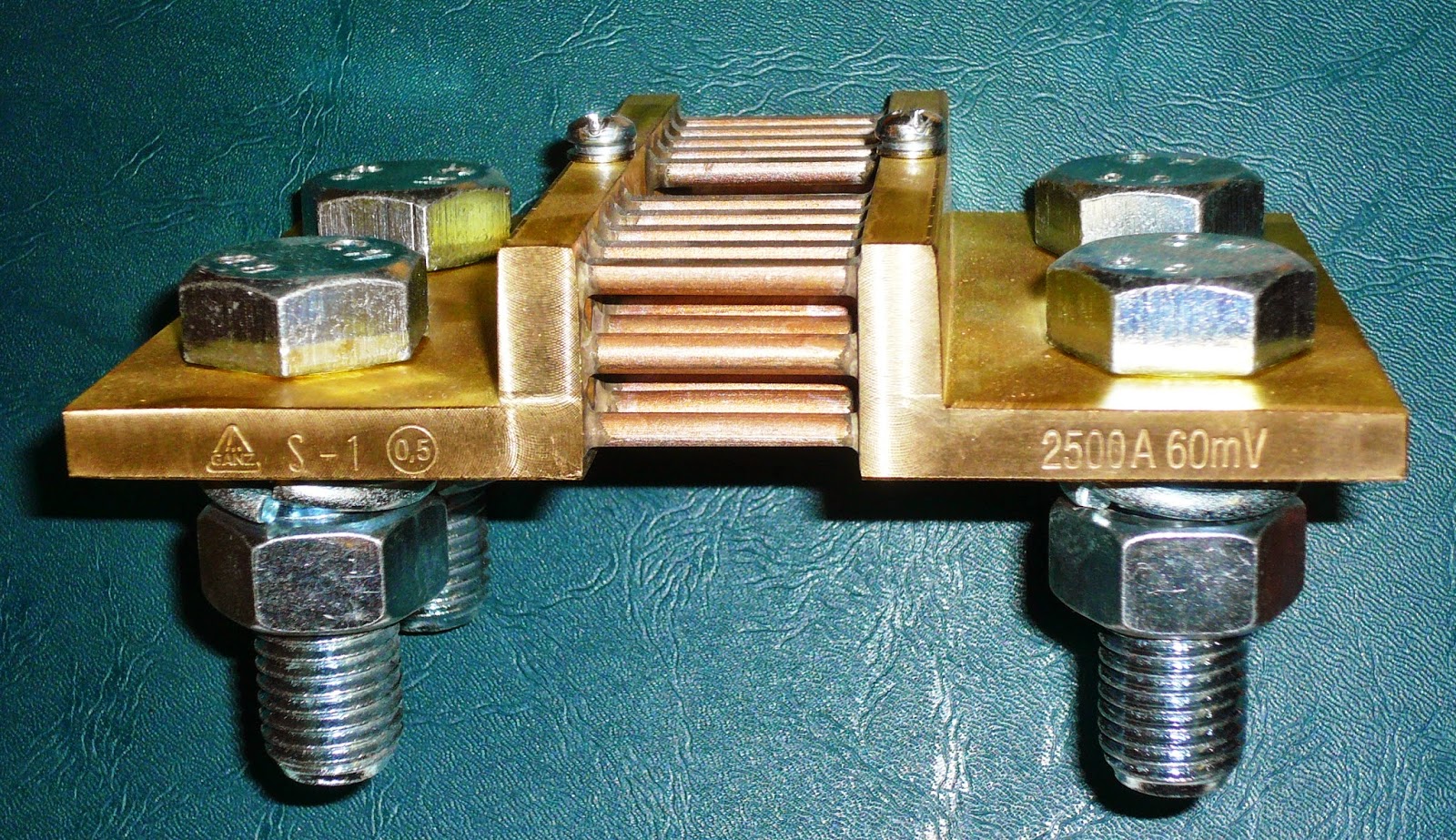

Types of winding are usually associated measurement devices as well as decade banks. However, the downside is more on difficult process of manufacturing. There have been various types of wirewound resistors that have been categorized into precision and power types. These are being modified for distinct ranges of applications in temperature sensors, potentiometers and current.

A wire resistor is usually found in a circuit breaker or as a fuse. In order to provide fusible resistors, their manufacturers must associated small springs in one end of resistors. Whenever the current and the heat through a resistor gets high enough, the solders will melt while springs are popping up when the circuit opened.